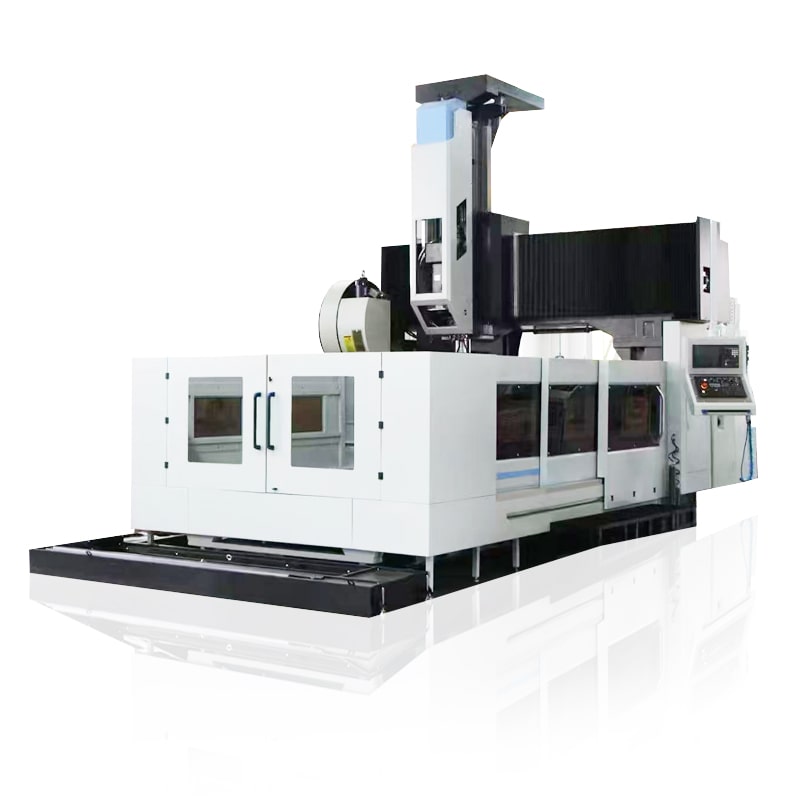

GMC4022 Gantry Milling Machine — Designed to Meet the Needs of Large Mold Processing

CNC Gantry Milling Machine GMC4022 Equipment Introduction The GMC4022 Gantry Mill.

What is a CNC Gantry CNC Milling Machine?

A CNC gantry CNC milling machine is a high-precision, high-rigidity CNC machining equipment designed for milling, drilling, boring, tapping, and contour machining of large parts. It features a gantry structure where the main spindle traverses the workpiece, moving vertically, horizontally, and laterally, enabling three-axis or multi-axis simultaneous machining. The machine offers long travel, high load capacity, and stable cutting performance, meeting the demands of aerospace, energy, mold, and heavy machinery industries for large workpieces.

Main Features:

Gantry Structure: High rigidity of the bed and columns, suitable for heavy cutting and large workpieces

High-Precision Guideways: Linear or rolling guideways ensure smooth feed and accurate positioning

Large Travel: X, Y, Z axes with extended travel for machining oversized components

Multi-Axis Interpolation: Supports 3-axis, 4-axis, or 5-axis simultaneous machining for complex surfaces

High-Rigidity Spindle: Provides stable cutting and excellent surface finish under heavy loads

Automation Compatibility: Can be equipped with automatic tool changer, robotic loading/unloading for batch production

Main Application Industries:

1. Aerospace Industry: Machining large structural components like aircraft fuselage frames, wing beams, and engine mounts. Requires high-precision, multi-face, and complex surface machining.

2. Energy Equipment Industry: Used for wind turbine bases, generator housings, gas turbine parts, pump bodies. Requires long-term stable machining, high concentricity, and assembly precision.

3. Construction Machinery Industry: Machining large machine frames, connecting seats, hydraulic components, gearbox housings. Heavy cutting capability for large and high-strength materials.

4. Shipbuilding Industry: Large outfitting parts, bearing housings, propeller brackets. Ensures surface finish and dimensional consistency.

5. Mold Manufacturing Industry: Machining large mold bases, die-casting molds, injection molds. High rigidity and multi-axis capability ensure high-precision complex mold machining.

Frequently Asked Questions (FAQ):

1. What is the difference between a large gantry milling machine and a regular vertical or horizontal machining center? Gantry structure is suitable for large workpieces, providing higher rigidity and less vibration; vertical or horizontal machining centers are better for medium to small parts with limited travel and load; gantry machines enable long-term heavy cutting for large structural parts.

2. What materials can be machined? Steel, cast iron, stainless steel, aluminum alloys, copper, titanium alloys, and composites. Suitable for heavy cutting and high-precision complex machining.

3. How to choose the right model? Based on the maximum part size (X/Y/Z travel), workpiece weight and material hardness, required machining accuracy and surface finish, need for multi-axis machining or automated loading/unloading.

4. Daily maintenance tips: Regularly check guideways, ball screws, and spindle lubrication. Keep the worktable and bed clean to avoid chip accumulation. Calibrate machine accuracy and inspect control and servo systems. Apply anti-rust and moisture protection during long-term shutdowns.

5. Main advantages of a large gantry CNC milling machine: High-rigidity gantry structure suitable for heavy cutting and large workpieces. High-precision guideways and spindle ensure machining quality. Large travel accommodates oversized parts. Multi-axis capability allows complex surface machining. Compatible with automated loading and batch production. Stable operation, easy maintenance, long service life.