High-Efficiency Machining Powerhouse!TCK700DY Achieves the Perfect Integration of Turning and Milling.

Brand:ALLES CNC

Model:ALTCK700DY

Dimensions:45000×2300×2550

Price:$79000(Standard Edition)/$95000(Pro Edition)

Availability:400 pieces of inventory available for sale every month

Certification:Meeting CE Standards in Terms of Quality & Safety

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Payment Method:T/T/ Credit Cards

Product Description

TCK700DY Turn-Mill CNC Machine – Product Introduction

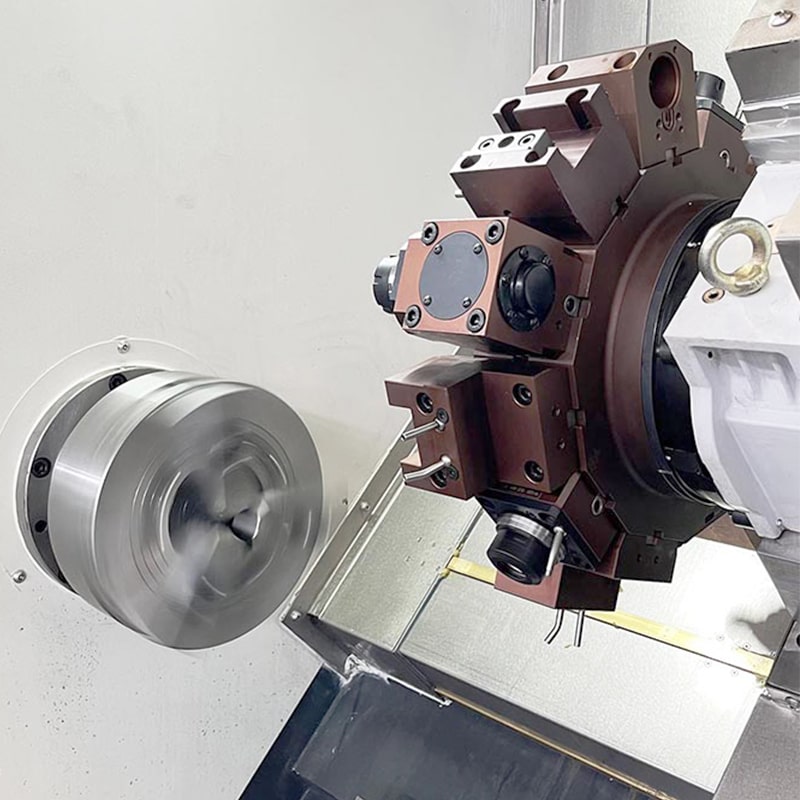

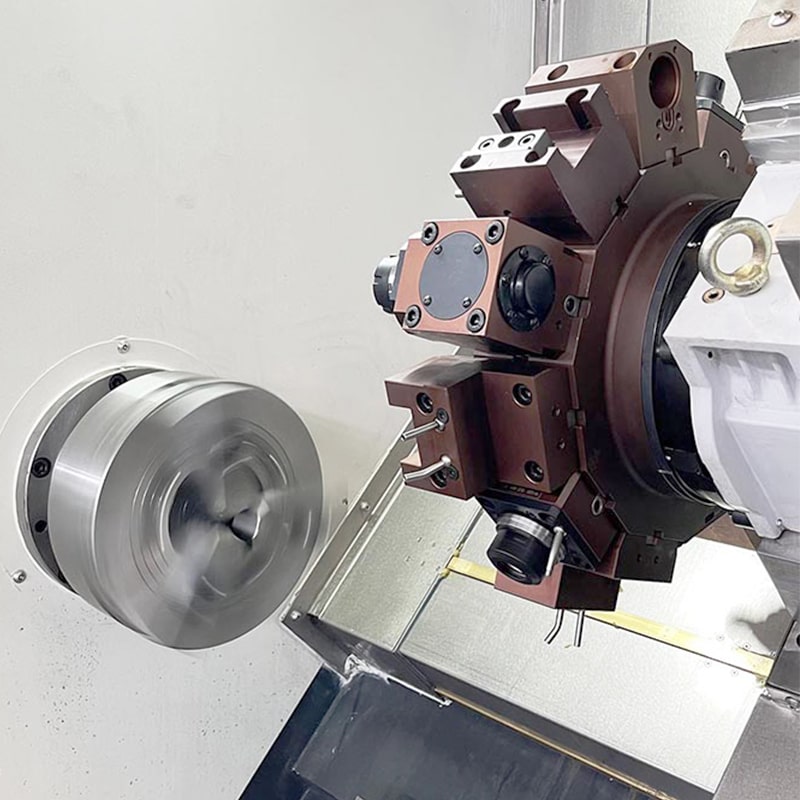

The TCK700DY Turn-Mill CNC Machine is an advanced multi-functional, high-precision, and high-efficiency CNC machining center. It perfectly integrates turning and milling functions, enabling complex multi-process machining of parts in a single setup. This significantly improves production efficiency, reduces secondary setup errors, and ensures consistent high precision, making it an ideal choice for modern smart manufacturing and high-end component production.

The machine features a high-rigidity bed structure and precision guideways, combined with a large-diameter, high-precision spindle and a high-torque servo drive system, ensuring outstanding stability and accuracy even under heavy-duty cutting conditions. With its multi-axis simultaneous machining capability, the TCK700DY can process threads, grooves, bosses, and complex contours, completing multiple operations in one setup, thereby shortening production cycles and reducing labor costs.

Equipped with an advanced CNC control system, the machine supports intelligent tool compensation, program editing, automatic fault diagnosis, and multiple machining modes. It is easy to operate and highly reliable. Optional features such as automatic loading/unloading devices, hydraulic chucks, tailstocks, and automatic chip conveyors enable efficient automated production, meeting the demands of modern smart and unmanned manufacturing.

Thanks to its high rigidity, multi-functionality, intelligent control, and high efficiency, the TCK700DY Turn-Mill CNC Machine is widely used in automotive parts, engineering machinery, aerospace, energy equipment, and mold manufacturing, providing manufacturers with precise, efficient, and reliable production solutions.

Opcional

Opcional

Hydraulic Steady Frame: Type C, self-centering range

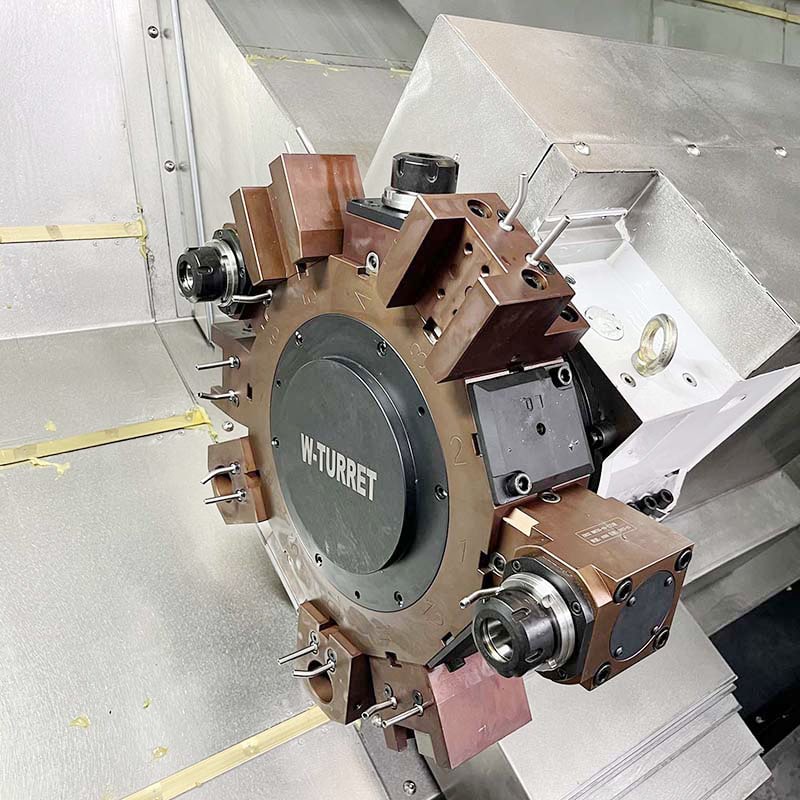

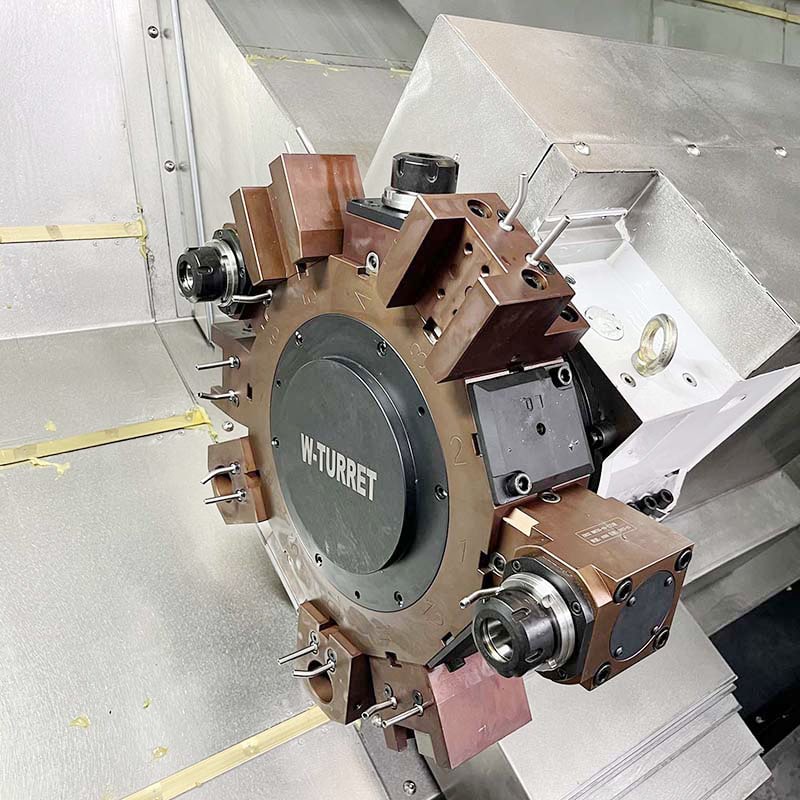

Power Turret: BMT55 / BMT65

Y Axis (Direct Connection Structure): Hard rail with hydraulic locking during static processing

Servo Programmable Tailstock: Servo motor control for precise positioning

Sub-Spindle: A2-6-79

ALTCK700DY Main Features and Advantages

Turn-Mill Compound Function

ALTCK700DY Main Features and Advantages

Turn-Mill Compound Function

Equipped with both turning and milling capabilities, the machine can complete multiple processes in a single setup, eliminating repeated handling and secondary setups, thereby improving machining efficiency and dimensional accuracy.

High-Rigidity Machine Structure

Featuring a high-rigidity bed and precision guideways, combined with a large-diameter spindle and high-torque servo system, the machine ensures stability and cutting precision even under heavy-duty machining conditions.

High-Precision CNC System

Equipped with a reliable CNC control system (such as FANUC, Siemens, or high-performance domestic systems), supporting intelligent tool compensation, program editing, fault diagnosis, and other functions. It is easy to operate and highly reliable.

Multi-Axis Simultaneous Machining Capability

Supports multi-axis simultaneous machining, enabling high-precision processing of complex surfaces, threads, grooves, discs, and shaft-type components.

Automation and Expandable Options

Optional features include automatic loading/unloading devices, hydraulic chucks, tailstocks, and automatic chip conveyors, enhancing production efficiency and enabling unmanned machining.

Technical Advantages

Technical Advantages

High rigidity with excellent vibration resistance

Multiple processes completed in a single setup, shortening production cycles

High machining accuracy, with repeat positioning precision up to ≤0.004 mm

Capable of processing complex parts and supporting batch production

Flexible configuration to meet the needs of various industriesaccessories

Capable of processing complex parts and supporting batch production

TCK700DY Applicable Industries

The TCK700DY Turn-Mill CNC Machine, with its high rigidity, multifunctionality, and precision, is widely applicable across multiple industrial sectors, capable of meeting the complex machining requirements of various components.

Automotive Parts Manufacturing

In the automotive industry, the TCK700DY efficiently machines engine shafts, drive shafts, gears, hubs, and brake discs. Its turn-mill compound capability allows multiple processes to be completed in a single setup, significantly improving production efficiency while ensuring dimensional accuracy and surface quality, meeting the high precision and productivity demands of modern automotive manufacturing.

Construction Machinery Components

For construction machinery, the TCK700DY can process hydraulic rods, gear shafts, support shafts, and large load-bearing disc components. The machine’s high-rigidity bed and large-diameter spindle ensure stable machining under heavy cutting conditions, satisfying the strength and durability requirements of construction machinery parts.

Aerospace Precision Components

In the aerospace industry, the TCK700DY can machine high-precision shafts, propeller shafts, hydraulic components, and aerospace engine parts. Its multi-axis simultaneous machining capability and high-precision CNC system enable the production of complex surfaces and intricate structures, meeting the stringent standards for accuracy, surface quality, and reliability required in aerospace applications.

Energy Equipment Shafts and Discs

In wind power, turbines, generators, and oil & gas equipment manufacturing, the TCK700DY can machine main shafts, rotors, bearing housings, and large disc components. Its rigid structure and powerful cutting capacity ensure stable machining of long shafts and support batch production, enhancing efficiency in energy equipment manufacturing.

Mold and Tooling Production

The TCK700DY is also ideal for mold and tooling applications, capable of machining various molds, gauges, and precision fixtures. Its high-precision machining capability and ability to complete multiple processes in a single setup shorten production cycles and guarantee dimensional and geometric accuracy, improving the quality and efficiency of molds and tools.

Turn-Mill CNC Fun Facts | Quick Knowledge

1.What is Turn-Mill Machining?

Turn-Mill combines turning and milling functions in one CNC machine. It allows multiple processes to be completed in a single setup, saving time, reducing errors, and improving precision.

2.Why Use a Turn-Mill CNC Machine?

Fewer setups → minimize handling errors

Higher efficiency → one machine, multiple functions

Complex parts → perfect for shafts, discs, and contoured surfaces

3.What Does Multi-Axis Simultaneous Machining Mean?

Modern turn-mill machines can move multiple axes at the same time—spindle, turret, and milling tools work together. This makes it possible to machine threads, grooves, and complex surfaces in one setup.

Pro Tip

The main advantage of turn-mill machines is completing multiple operations in one setup, but careful programming and tool selection are key to achieving maximum efficiency and precision.

Capable of processing complex parts and supporting batch production

| Specifications | Unit | Parameter | |||

| Processing range | The maximum turning diameter on the bed | mm | Φ780 | ||

| The maximum turning diameter on the saddle | mm | Φ500 | |||

| Recommended turning diameter | mm | Φ650 | |||

| Effective processing length | mm | 900 | |||

| Spindle | Spindle head type | mm | A2-8 | A2-11(optional) | |

| Spindle through hole diameter | mm | 88 | 105 | 132 | |

| Bar stock diameter ≤ | mm | 75 | 92 | 115 | |

| Maximum spindle speed | r/min | 3000 | 2500 | 1600 | |

| Main motor rated output | Kw | 15-21 | 22-30 | ||

| The maximum output torque of the main shaft | NM | 573 | |||

| Saddle | Slope | DEG | 45 ° | ||

| Moving distance X | mm | 350+20 | |||

| Fast movement speed X/Z | m/min | 16/24 | |||

| Servo motor X/Y/Z | KW | 3/3/3(4) | |||

| Turret | Form | servo hydraulic |

BMT65 horizontal 12 stations |

||

| Adjacent tool change time | S | 0.5 | |||

| Number of tools | / | 12 stations | |||

| Tool Dimensions (Turning / Boring) | mm | 32×32/Φ32(40) | |||

| Power Turret Power | KW | 7.5-11 | |||

| Y-axis travel | mm | ±75 | |||

| Machine dimensions | mm | 45000*2300*2550 | |||

| Machine net weight/gross weight | mm | 7000/7500 | |||

TCK700DY Applicable Industries

The TCK700DY Turn-Mill CNC Machine, with its high rigidity, multifunctionality, and precision, is widely applicable across multiple industrial sectors, capable of meeting the complex machining requirements of various components.

Automotive Parts Manufacturing

In the automotive industry, the TCK700DY efficiently machines engine shafts, drive shafts, gears, hubs, and brake discs. Its turn-mill compound capability allows multiple processes to be completed in a single setup, significantly improving production efficiency while ensuring dimensional accuracy and surface quality, meeting the high precision and productivity demands of modern automotive manufacturing.

Construction Machinery Components

For construction machinery, the TCK700DY can process hydraulic rods, gear shafts, support shafts, and large load-bearing disc components. The machine’s high-rigidity bed and large-diameter spindle ensure stable machining under heavy cutting conditions, satisfying the strength and durability requirements of construction machinery parts.

Aerospace Precision Components

In the aerospace industry, the TCK700DY can machine high-precision shafts, propeller shafts, hydraulic components, and aerospace engine parts. Its multi-axis simultaneous machining capability and high-precision CNC system enable the production of complex surfaces and intricate structures, meeting the stringent standards for accuracy, surface quality, and reliability required in aerospace applications.

Energy Equipment Shafts and Discs

In wind power, turbines, generators, and oil & gas equipment manufacturing, the TCK700DY can machine main shafts, rotors, bearing housings, and large disc components. Its rigid structure and powerful cutting capacity ensure stable machining of long shafts and support batch production, enhancing efficiency in energy equipment manufacturing.

Mold and Tooling Production

The TCK700DY is also ideal for mold and tooling applications, capable of machining various molds, gauges, and precision fixtures. Its high-precision machining capability and ability to complete multiple processes in a single setup shorten production cycles and guarantee dimensional and geometric accuracy, improving the quality and efficiency of molds and tools.

Turn-Mill CNC Fun Facts | Quick Knowledge

1.What is Turn-Mill Machining?

Turn-Mill combines turning and milling functions in one CNC machine. It allows multiple processes to be completed in a single setup, saving time, reducing errors, and improving precision.

2.Why Use a Turn-Mill CNC Machine?

Fewer setups → minimize handling errors

Higher efficiency → one machine, multiple functions

Complex parts → perfect for shafts, discs, and contoured surfaces

3.What Does Multi-Axis Simultaneous Machining Mean?

Modern turn-mill machines can move multiple axes at the same time—spindle, turret, and milling tools work together. This makes it possible to machine threads, grooves, and complex surfaces in one setup.

Pro Tip

The main advantage of turn-mill machines is completing multiple operations in one setup, but careful programming and tool selection are key to achieving maximum efficiency and precision.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More