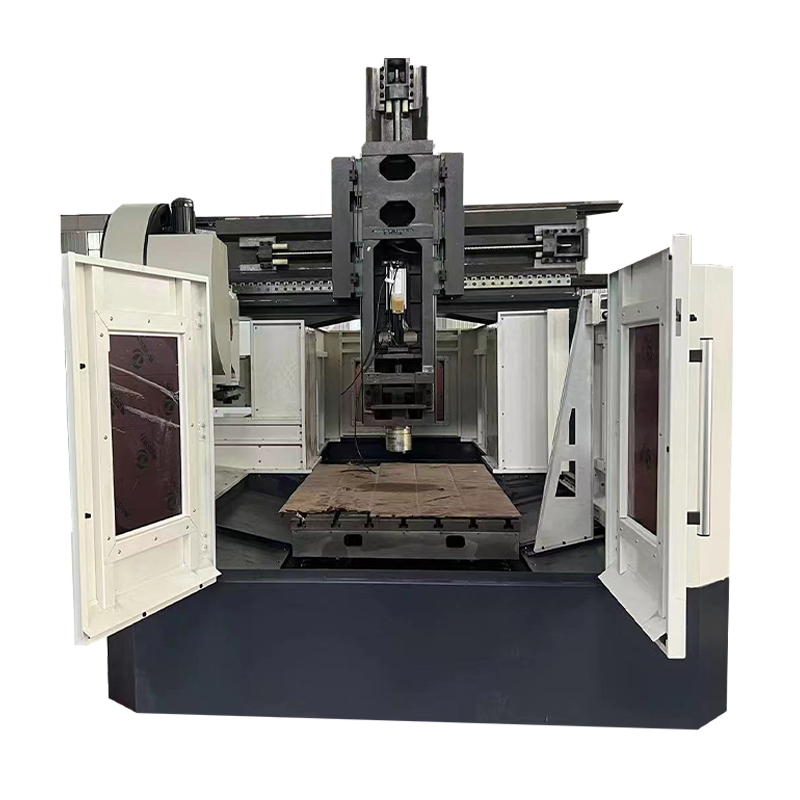

Large Travel + Heavy Cutting — Gantry milling machine1813 Helps You Tackle Complex Machining Challenges with Ease!

The GMC1813 gantry machining center is a large-scale CNC machine that combines high rigidity, high precision, and powerful cutting capabilities. It is specifically designed to meet the efficient machining needs of large workpieces and complex components. The machine adopts a gantry structure with a stable and symmetrical bed design, offering excellent thermal stability and vibration resistance to ensure machining accuracy during long processing cycles.

This equipment is ideal for multi-face, multi-process composite machining of medium to large workpieces such as molds, structural parts, and construction machinery components. The spindle system supports high-torque heavy cutting and can be equipped with either a geared or direct-drive spindle according to customer requirements, allowing seamless transition from rough to fine machining.

The transmission system features a combination of high-precision ball screws and linear guideways, enhancing feed speed and repeat positioning accuracy. Together with a fully enclosed protective system and centralized lubrication, it effectively extends the service life of the equipment and reduces maintenance costs.

Widely used in mold manufacturing, automotive parts, rail transit, construction machinery, and the aerospace industry, the GMC1813 is an ideal machining solution for modern manufacturing enterprises seeking high efficiency, high precision, and high reliability.

This equipment is ideal for multi-face, multi-process composite machining of medium to large workpieces such as molds, structural parts, and construction machinery components. The spindle system supports high-torque heavy cutting and can be equipped with either a geared or direct-drive spindle according to customer requirements, allowing seamless transition from rough to fine machining.

The transmission system features a combination of high-precision ball screws and linear guideways, enhancing feed speed and repeat positioning accuracy. Together with a fully enclosed protective system and centralized lubrication, it effectively extends the service life of the equipment and reduces maintenance costs.

Widely used in mold manufacturing, automotive parts, rail transit, construction machinery, and the aerospace industry, the GMC1813 is an ideal machining solution for modern manufacturing enterprises seeking high efficiency, high precision, and high reliability.

Product Description

The GMC1813 gantry machining center delivers exceptional machining performance, specifically designed for heavy cutting, large workpieces, and complex structural components. With a high-rigidity structure and large travel configuration, it excels in multi-surface and multi-process machining tasks, handling everything from roughing to finishing with ease. The high-torque spindle system, combined with a precision transmission system and stable guideway layout, ensures consistent accuracy and machining stability during long operations.

Thanks to its outstanding capabilities, the GMC1813 is widely used in mold manufacturing, construction machinery, automotive parts, rail transit, and the aerospace industry. It is especially well-suited for processing large, complex, and high-precision components, making it an ideal solution for modern manufacturers seeking to enhance their machining capacity and productivity.

Thanks to its outstanding capabilities, the GMC1813 is widely used in mold manufacturing, construction machinery, automotive parts, rail transit, and the aerospace industry. It is especially well-suited for processing large, complex, and high-precision components, making it an ideal solution for modern manufacturers seeking to enhance their machining capacity and productivity.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More