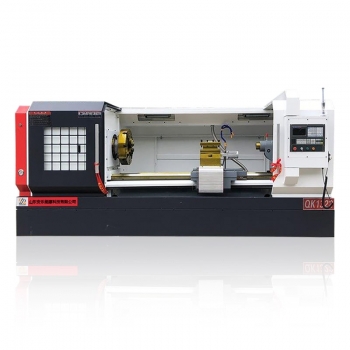

Powerful Rigidity QK1322 CNC Lathe | Efficient Turning Solution for Large-Size Parts

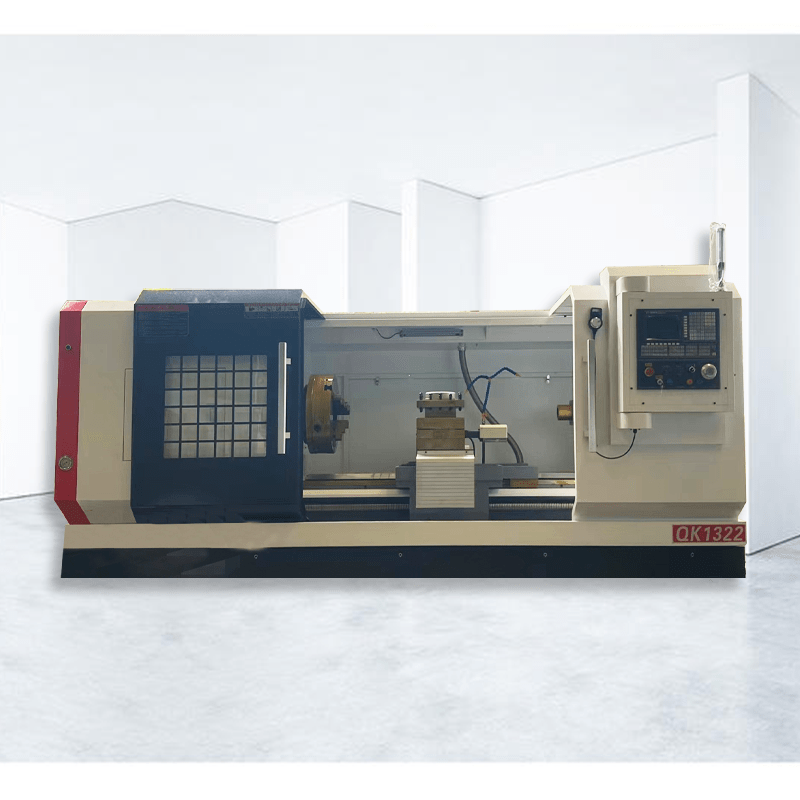

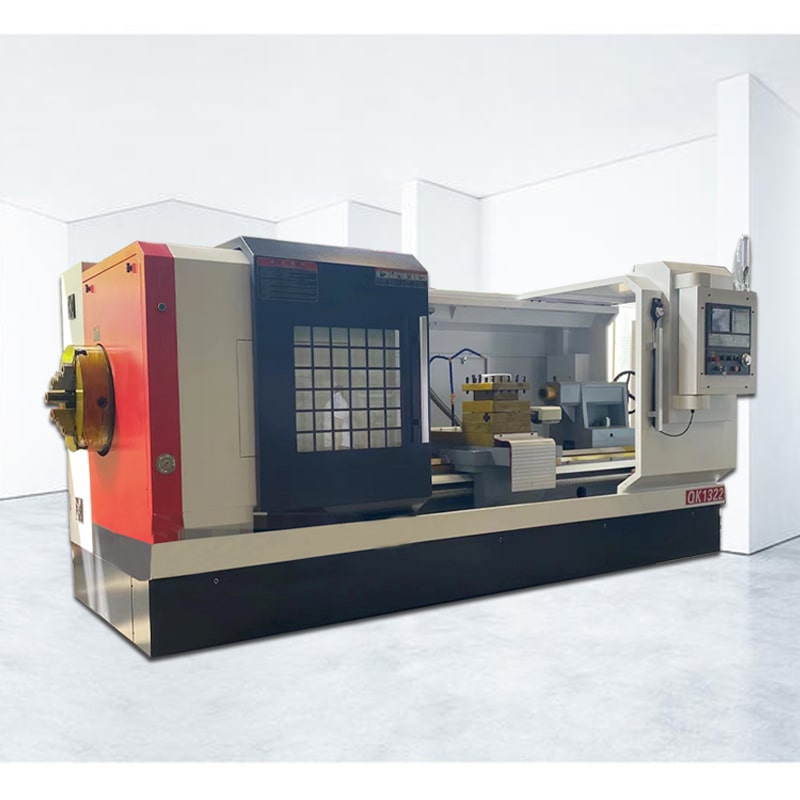

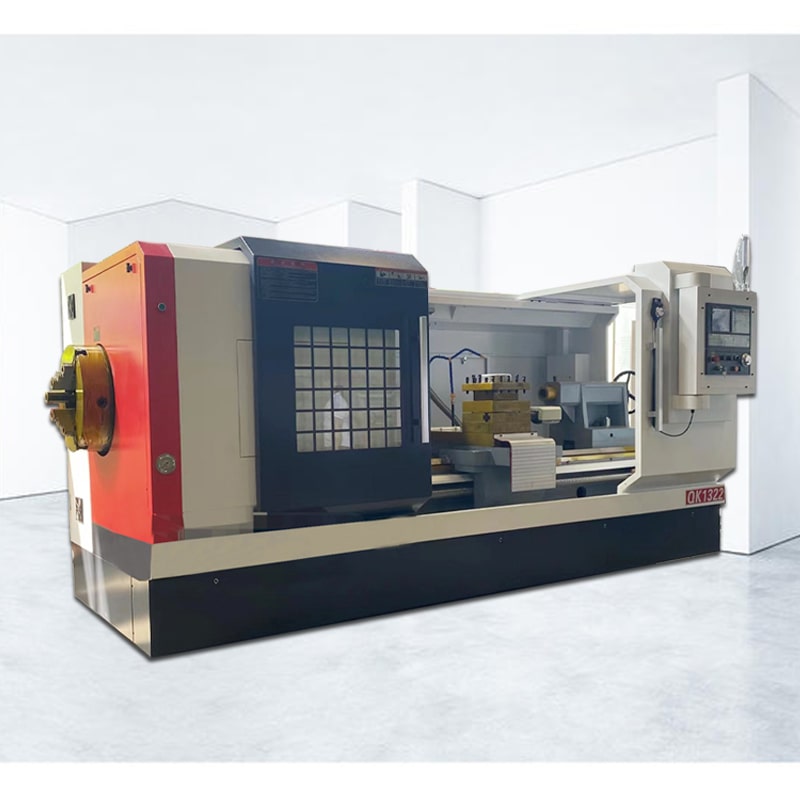

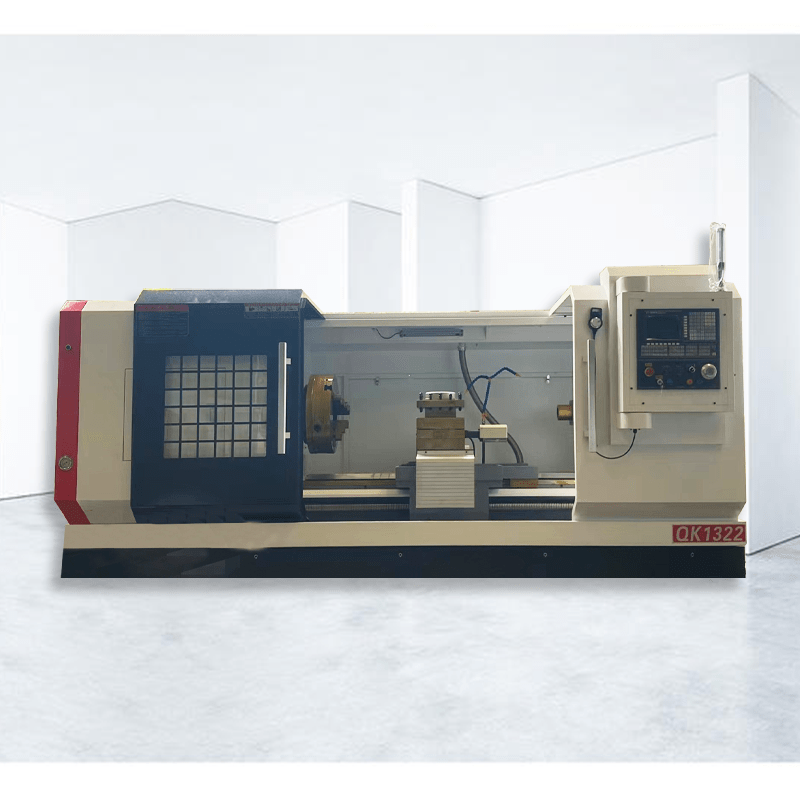

CNC Lathe ALQK1322 CNC pipe thread lathe.

CNC Lathe Pipe Thread Lathe Machine ALQK1322 CNC pipe threading lathe

CNC Lathe Pipe Thread Lathe Machine ALQK1322 CNC pipe threading lathe.

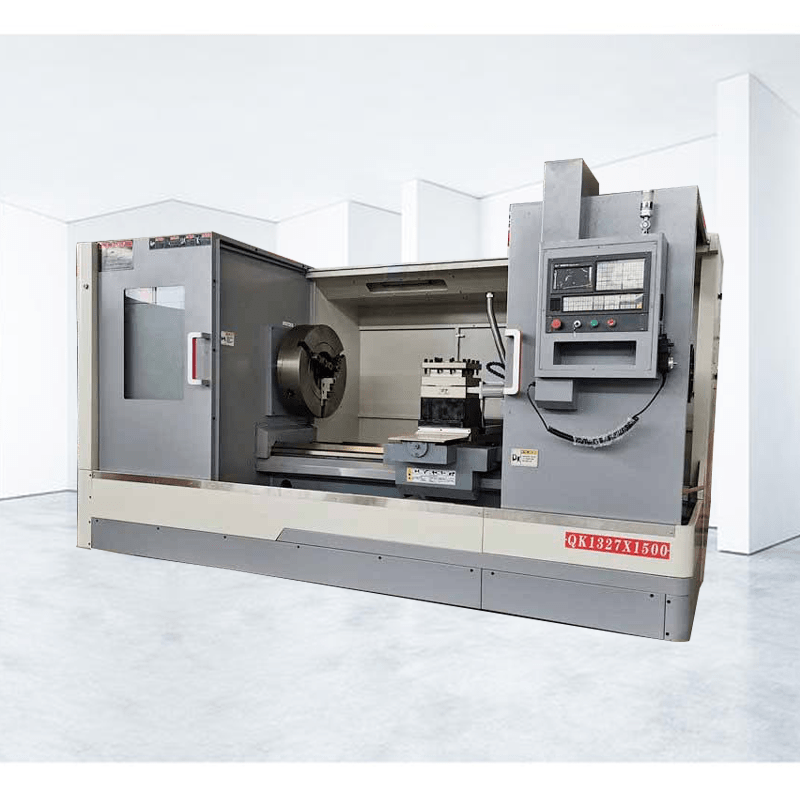

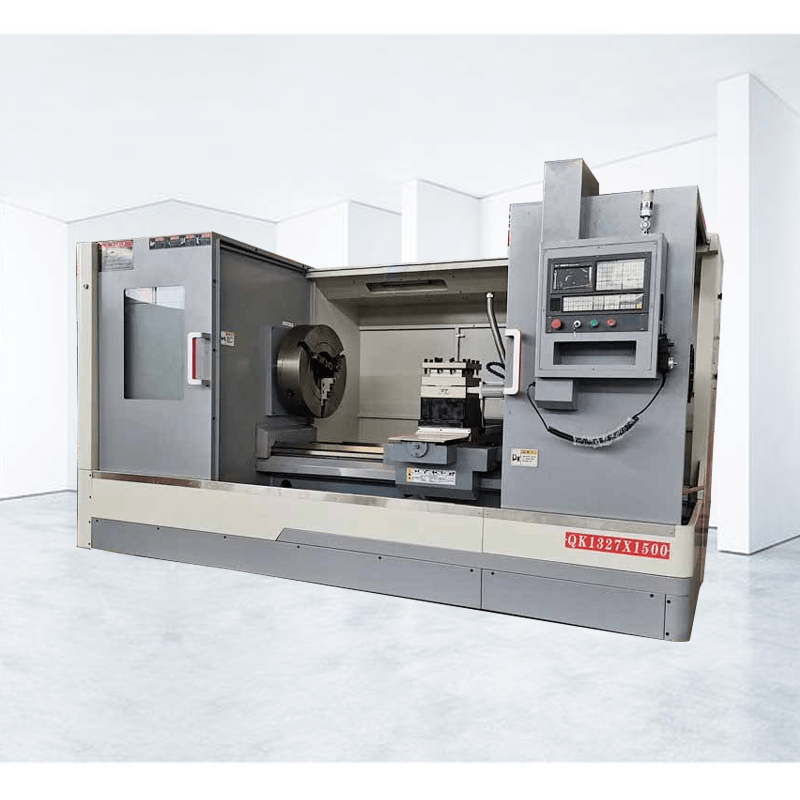

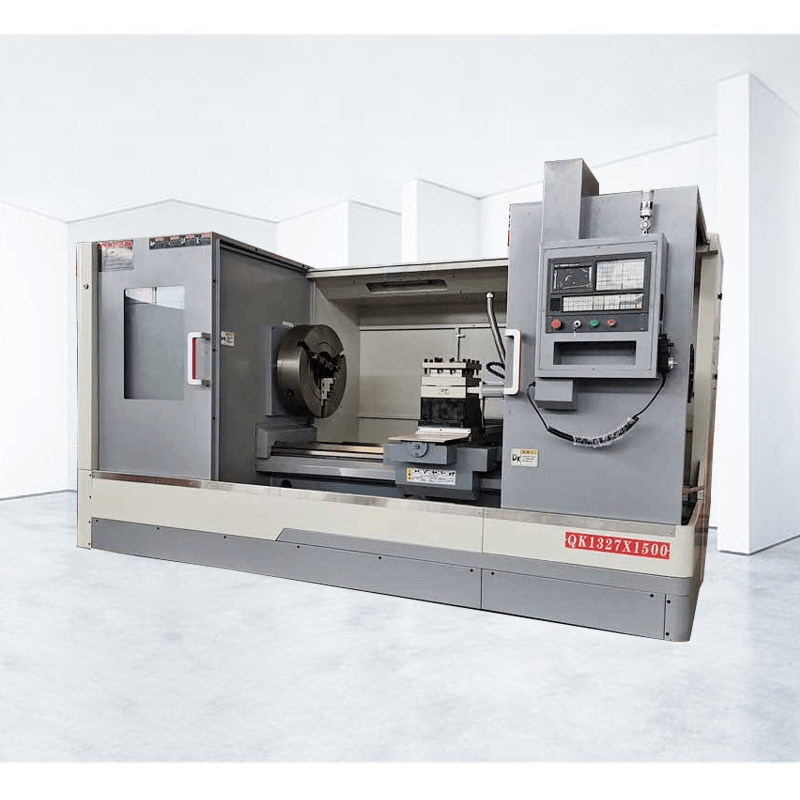

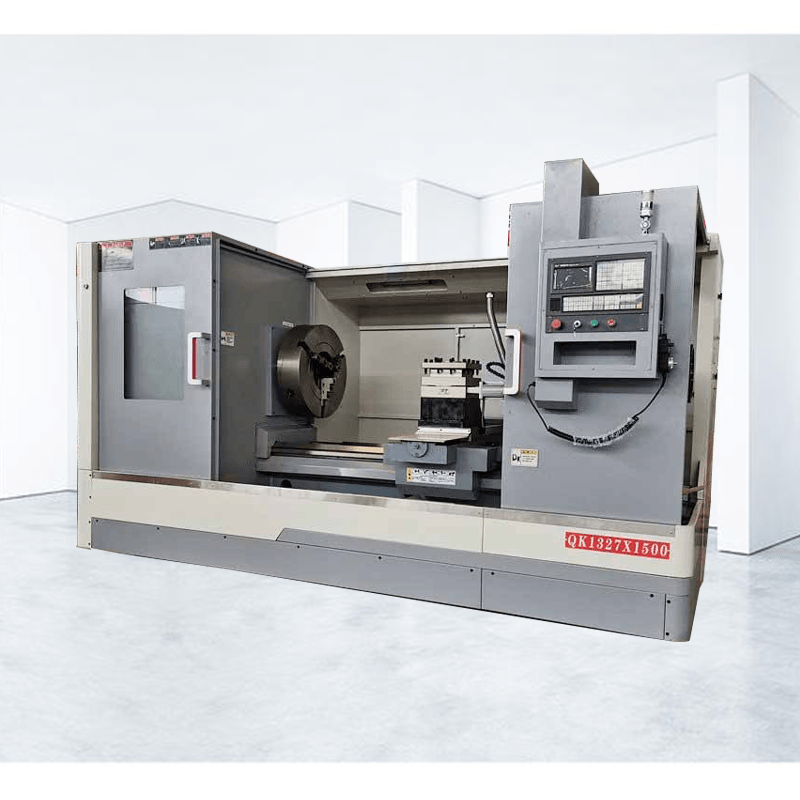

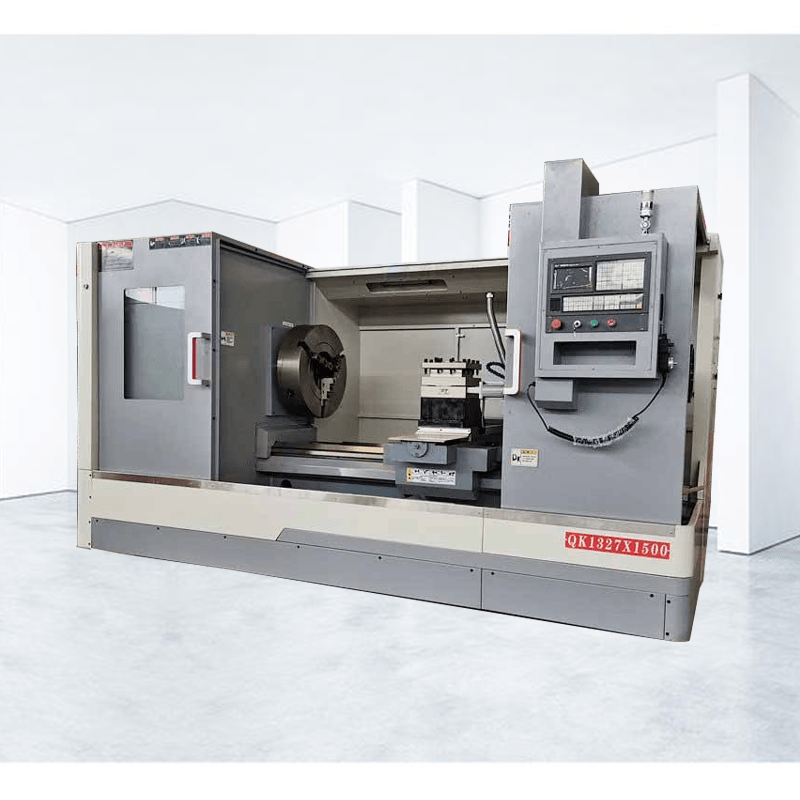

CNC Oil pipe lathe ALQK1327 CNC pipe threading lathe

CNC Oil pipe lathe ALQK1327 CNC pipe threading lathe.

CNC Lathe Pipe Thread Lathe Machine ALQK1327 CNC Oil Lathe

CNC Lathe Pipe Thread Lathe Machine ALQK1327 CNC Oil Lathe.

CNC Lathe Pipe Thread Lathe Machine ALQK1327 CNC Turning Machine

CNC Lathe Pipe Thread Lathe Machine ALQK1327 CNC Turning Machine.

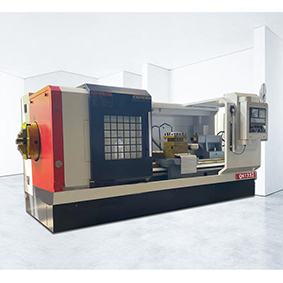

CNC lathe pipe thread lathe machine ALQK1332 CNC pipe threading lathe

CNC lathe pipe thread lathe machine ALQK1332 CNC pipe threading lathe .

CNC pipe thread lathe ALQK1327 CNC turning machine

CNC pipe thread lathe ALQK1327 CNC turning machine.

CNC Oil pipe lathe ALQK1322 CNC pipe threading lathe

CNC Oil pipe lathe ALQK1322 CNC pipe threading lathe.

CNC pipe thread lathe ALQK1332 CNC lathe pipe thread lathe machine

CNC pipe thread lathe ALQK1332 CNC lathe pipe thread lathe machine.

CNC Oil pipe lathe ALQK1332 CNC pipe thread lathe

CNC Oil pipe lathe ALQK1332 CNC pipe thread lathe.

CNC lathe pipe thread lathe machine ALQK1327 CNC Oil pipe lathe

CNC lathe pipe thread lathe machine ALQK1327 CNC Oil pipe lathe.

What is a Pipe Thread CNC Lathe?

A Pipe Thread CNC Lathe is a high-precision CNC turning machine specifically designed for machining various internal and external threads (such as tapered pipe threads, cylindrical threads, metric threads, imperial threads, etc.) and long-shaft workpieces.

The machine usually features a large spindle bore, with diameters up to Φ105mm, Φ130mm, or larger, allowing long pipes to be fed through directly. Combined with a high-rigidity bed, wide guideways, and a powerful servo system, it ensures excellent stability and high precision under heavy cutting loads.

Main Application Industries

1. Oil & Gas Industry: Used for machining oil pipes, drill rods, joints, casings, flanges, and other components, achieving high-precision internal and external thread connections (e.g., API standard threads).

2. Hydraulic & Pneumatic Equipment Manufacturing: Machines hydraulic cylinder tubes, joints, valve bodies, and connecting pipes with threaded structures, ensuring sealing performance and consistent accuracy.

3. Construction Machinery & Energy Equipment: Processes hydraulic pipes, connecting tubes, wind power shafts, pump shafts, and other high-strength components, ensuring reliable threaded connections.

4. Building Pipeline & Firefighting Systems: Widely used for machining water supply and drainage pipes, firefighting pipe joints, steel pipe fittings, and quick-connect threaded components.

5. Automotive & Transportation Industry: For production of drive shaft tubes, connectors, and axle-threaded sections of medium and large pipe-type parts.

6. General Mechanical Manufacturing: Suitable for precision batch machining of medium-to-large diameter pipes, shafts, flanges, and threaded connection parts.

Frequently Asked Questions (FAQ)

1. How does it differ from a standard CNC lathe?

Standard lathes have smaller spindle bores and are unsuitable for through-pipe machining.

Pipe thread lathes feature larger spindle bores and higher rigidity, designed specifically for threaded pipe cutting, enabling high-torque heavy cutting and long-shaft support.

2. What thread types can be machined?

Automatically processes multiple thread forms:

— Metric threads (Metric)

— Imperial threads (BSP, UNC, UNF)

— Tapered threads (NPT, PT, API)

— Custom threads (per customer specifications)

3. What materials can be machined?

Suitable for a wide range of metals:

— Carbon steel

— Stainless steel

— Alloy steel

— Cast iron

— Aluminum

— Copper

— Titanium alloys

4. How to choose the right model?

Consider the following:

— Maximum workpiece diameter and length

— Thread type (API, G, NPT, etc.)

— Material hardness and cutting load

— Need for automatic feeding, tailstock support, or powered turret

5. Daily maintenance tips

— Keep spindle bore and guideways clean, prevent chip accumulation

— Regularly check ball screw and servo system clearance

— Inspect thread cutting tools for wear and alignment

— Check hydraulic system and coolant status

— Apply rust protection during long-term shutdowns

6. Main advantages of a Pipe Thread CNC Lathe

— High-rigidity structure, stable under heavy cutting

— Supports multiple standard thread types (API / BSP / NPT, etc.)

— Spindle bore design suitable for long pipe workpieces

— High precision and excellent surface finish

— Supports integration into automated production lines

— Easy maintenance and long service life