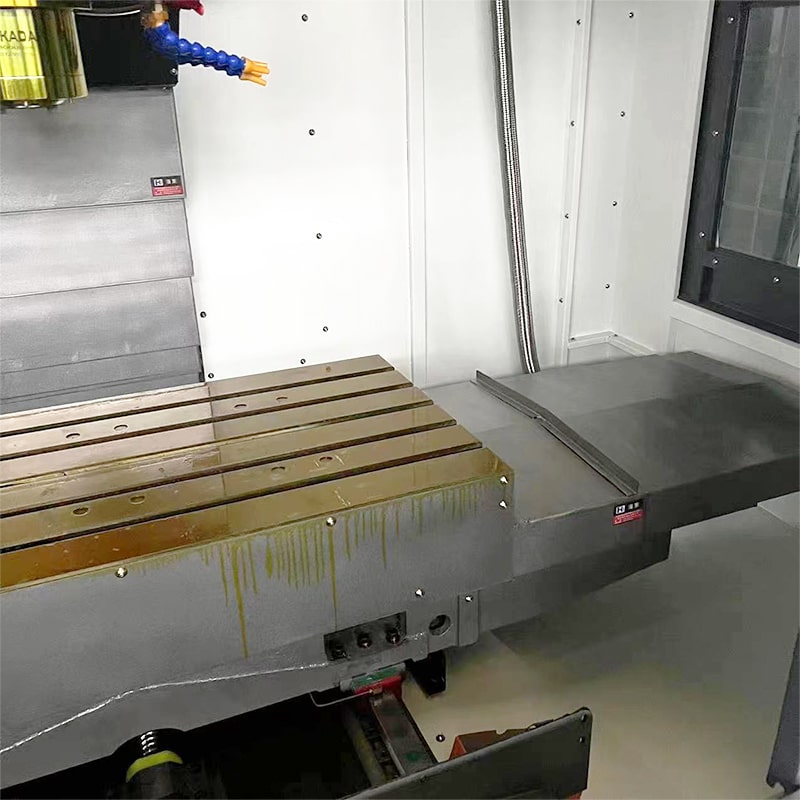

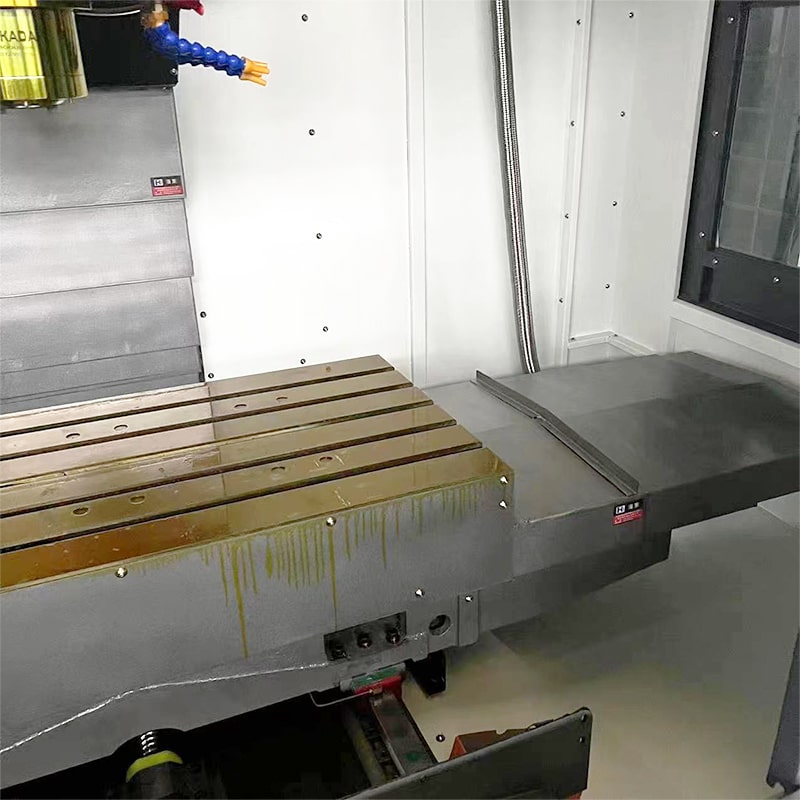

VMC1160 Vertical CNC Milling Machine — The First Choice for Mold Processing and Mechanical Parts Manufacturing

Brand - ALLES CNC

Model - ALVMC1160

Dimensions - 3200×2450×2650mm

Price - $23000(Standard Edition)/$28000(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Payment Method:T/T/ Credit Cards

Contact Us Video

Model - ALVMC1160

Dimensions - 3200×2450×2650mm

Price - $23000(Standard Edition)/$28000(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Payment Method:T/T/ Credit Cards

Contact Us Video

Product Description

VMC1160 Vertical Machining Center — Precision, Power, and Performance

The VMC1160 vertical CNC machining center is engineered to deliver outstanding performance for medium and large-sized part production. With generous travels of X1100mm, Y600mm, and Z600mm, and a spindle nose-to-table distance of 120–720mm, it offers the flexibility to handle complex, multi-process machining in a single setup.

Its 1200×600mm worktable supports up to 800kg, ensuring excellent stability even with heavy workpieces. High precision is guaranteed with ±0.008mm positioning accuracy and ±0.006mm repeatability, making it ideal for industries where accuracy is paramount.

Powered by an 11kW spindle motor and featuring a BT40 taper, the spindle runs at speeds up to 8000rpm, delivering both heavy-duty cutting strength and high-speed finishing capability. Equipped with a 24-tool arm-type automatic tool changer, with tool change times as fast as 3 seconds, it supports tools up to 250mm in length and 8kg in weight, significantly boosting productivity.

With a robust 7300kg structure and overall dimensions of 3200×2450×2650mm, the VMC1160 combines rigidity and durability with precision engineering. It is the perfect solution for mold manufacturing, automotive parts, aerospace components, and precision machinery, offering manufacturers a competitive edge in efficiency and quality.

Opcional

CNC system: GSK, KND, FANUC, Sie-mens.

Number of axes: 3 axes,4 axes, 5 axes (3 axes +cradle)

VMC1160 — Advantages and Features

Core Advantages

Large Travel, Multi-Process in One Setup

Travels of X1100 / Y600 / Z600 mm allow machining of larger parts, minimizing repositioning, reducing fixture costs, and improving overall efficiency and consistency.

High Load Capacity & Rigidity

A 1200×600 mm table with 800 kg load capacity and 7300 kg machine weight ensures stable performance during heavy cutting, reducing vibration and improving tool life.

High Accuracy & Repeatability

Positioning accuracy of ±0.008 mm and repeatability of ±0.006 mm make it ideal for precision components and mold cavities, ensuring stable quality and higher first-pass yield.

Powerful Spindle Performance

An 11 kW main motor with a BT40 spindle taper and 8000 rpm speed provides both strong cutting power and high-speed finishing capability.

High-Speed Tool Changing

Equipped with a 24-tool arm-type ATC, tool changes take as little as 3 seconds. Supports tools up to 250 mm in length and 8 kg in weight, minimizing downtime and improving cycle efficiency.

Ease of Operation & Maintenance

Standard ATC, automatic lubrication, coolant system, and full enclosure design ensure reliable operation, safety, and easy daily maintenance.

Wide Application & Fast ROI

Applicable in molds, automotive parts, structural components, and precision parts. By reducing setups and increasing yield, it provides faster return on investment.

Technical Features

Travel & Geometry

X-axis: 1100 mm; Y-axis: 600 mm; Z-axis: 600 mm.

Spindle nose-to-table: 120–720 mm; spindle center-to-column: 600 mm.

Worktable & Capacity

Table size: 1200×600 mm; Max load: 800 kg.

T-slot design for secure clamping of large parts and fixtures.

Transmission & Accuracy

Positioning accuracy: ±0.008 mm; Repeatability: ±0.006 mm.

Rapid traverse: 24 m/min.

Spindle System

Max speed: 8000 rpm; Taper: BT40; Motor power: 11 kW.

Balanced for heavy-duty cutting and high-speed finishing.

Tool Changer (ATC)

Arm type; 24 tools; Tool change time ~3 sec.

Supports tools up to 250 mm long and 8 kg in weight.

Machine Structure

Weight: 7300 kg; Dimensions: 3200×2450×2650 mm.

Rigid construction ensures stability and vibration resistance.

CNC Control & Automation

Compatible with FANUC, Siemens, Mitsubishi CNC systems.

Supports multi-axis interpolation, macro programming, auto-diagnostics, and remote monitoring.

| Item | Unit | Specification |

|---|---|---|

| Travel | ||

| X axis travel | mm | 1100 |

| Y axis travel | mm | 600 |

| Z axis travel | mm | 600 |

| Spindle nose to table surface | mm | 120–720 |

| Spindle center to column surface | mm | 600 |

| Worktable | ||

| Table size | mm | 1200 × 600 |

| Maximum table load | kg | 800 |

| T-slot | mm | – |

| Positioning accuracy | mm | ±0.008 |

| Repeat positioning accuracy | mm | ±0.006 |

| Rapid traverse speed (X/Y/Z) | m/min | 24 |

| Spindle | ||

| Spindle speed | rpm | 8000 |

| Spindle taper | - | BT40 |

| Main motor power | kW | 11 |

| ATC (Automatic Tool Changer) | ||

| Tool changer type | - | Arm type |

| Number of tools | pcs | 24 |

| Tool change time (T–T) | s | 3 |

| Max. tool length | mm | 250 |

| Max. tool weight | kg | 8 |

| Machine | ||

| Net weight | kg | 7300 |

| Overall dimensions (L × W × H) | mm | 3200 × 2450 × 2650 |

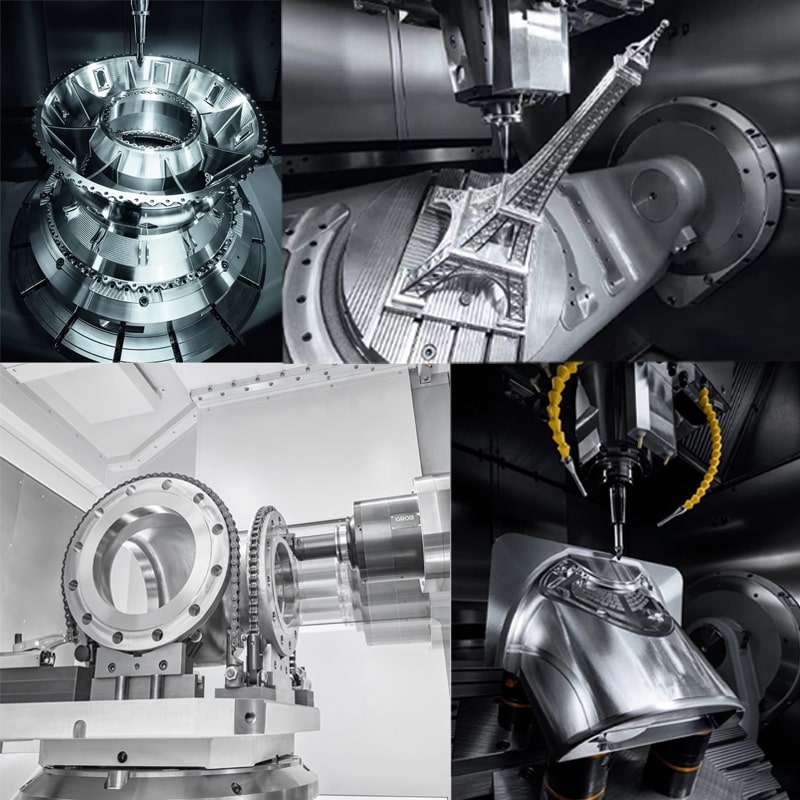

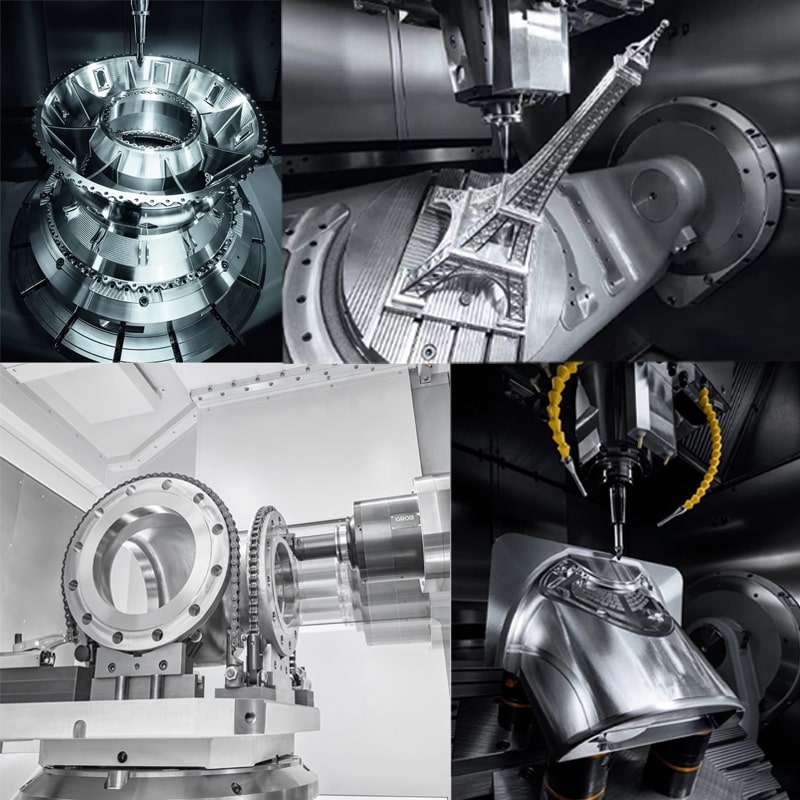

VMC1160 - Application Industries

1. Automotive Manufacturing: Finishing of engine cylinder blocks/cylinder heads, transmission housings, brackets, suspension parts, mold guides/sleeves, and fixtures.

2. Mold and Mold Manufacturing: Injection mold cavity/core molding, die-casting mold processing, and fine milling and pre-polishing of mold components (cavity, core, and die base).

3. Aerospace: Engine brackets, small structural parts, accessory flanges, test fixtures, fastener components, and aluminum alloy heat exchanger housings.

4. Medical Devices: Blank machining of orthopedic implants, surgical instruments, medical device frames and accessories, and positioning fixtures and gauges.

5. Energy, Oil & Gas: Valve bodies, flanges, pump bodies, pipe fittings, ferrules, and hydraulic components.

6. General Machinery Manufacturing and Transmission Parts: Small and medium-volume machining of gearbox housings, bearing bodies, couplings, pump frames, and transmission components. 7. Electronics and Heat Sinks: Radiator profile cutting, aluminum alloy housings, high-precision hole and locating groove machining.

8. Education, Training, and R&D: Machining course materials, prototype production, product verification, structural component samples, and trial production.

9. Precision Hardware, Furniture Hardware, and Small-to-Medium Processing: Small-batch customization of door and window hardware, hinges, connectors, and mechanical components.

VMC1160 Vertical Machining Center – FAQ (Knowledge Q&A)

Q1: What is the maximum workpiece size that the VMC1160 can handle?

A: The VMC1160 has a table size of 1200 × 600 mm and a maximum load capacity of 800 kg, making it suitable for medium-to-large workpieces such as automotive engine blocks, mold bases, and structural components.

Q2: What industries commonly use the VMC1160?

A: The VMC1160 is widely applied in automotive, aerospace, mold & die, medical devices, energy, and general machinery manufacturing. It is especially suitable for precision machining of complex parts requiring high accuracy and efficiency.

Q3: How does the VMC1160 improve machining efficiency?

A: Equipped with a 24-tool arm-type ATC (Automatic Tool Changer) and a high-speed 8000 rpm BT40 spindle, the VMC1160 supports rapid tool changes (just 3 seconds) and high-speed cutting, significantly reducing cycle time and increasing throughput.

Q4: What level of accuracy can the VMC1160 achieve?

A: The machine provides a positional accuracy of ±0.008 mm and a repeatability of ±0.006 mm, ensuring precise and consistent results even in high-volume production.

Q5: Why choose the VMC1160 over smaller machining centers?

A: Compared to smaller VMC models, the VMC1160 offers longer X/Y/Z travel (1100 × 600 × 600 mm), greater rigidity, and higher load capacity, allowing it to handle larger and heavier workpieces while maintaining superior precision.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More