CK6180×1500 CNC Lathe | The First Choice for Large-Diameter and Long Workpiece Machining!

Brand - ALLES CNC

Model - ALCK6180*1500

Dimensions - 3999×1900×2000mm

Price - $23500(Standard Edition)/$29999(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

Contact Us Video

Contact Us Video

Product Description

Product Introduction – CK6180×1500 CNC Lathe

The CK6180×1500 CNC lathe is a high-performance machine tool designed for machining large-diameter and long-length workpieces. The machine adopts a high-rigidity bed structure, fully stress-relieved to ensure long-term stability and accuracy without deformation.

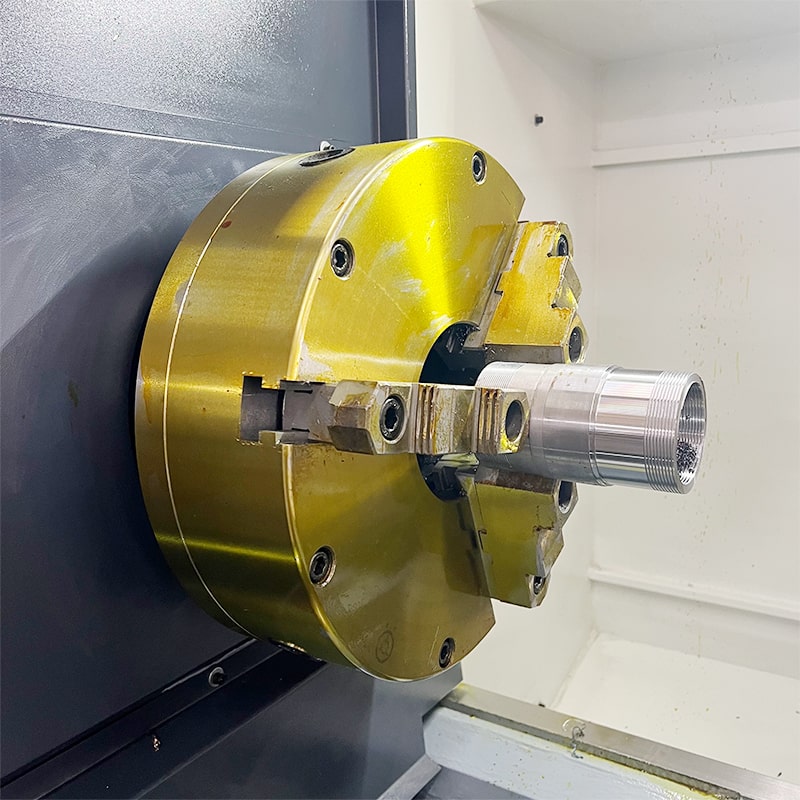

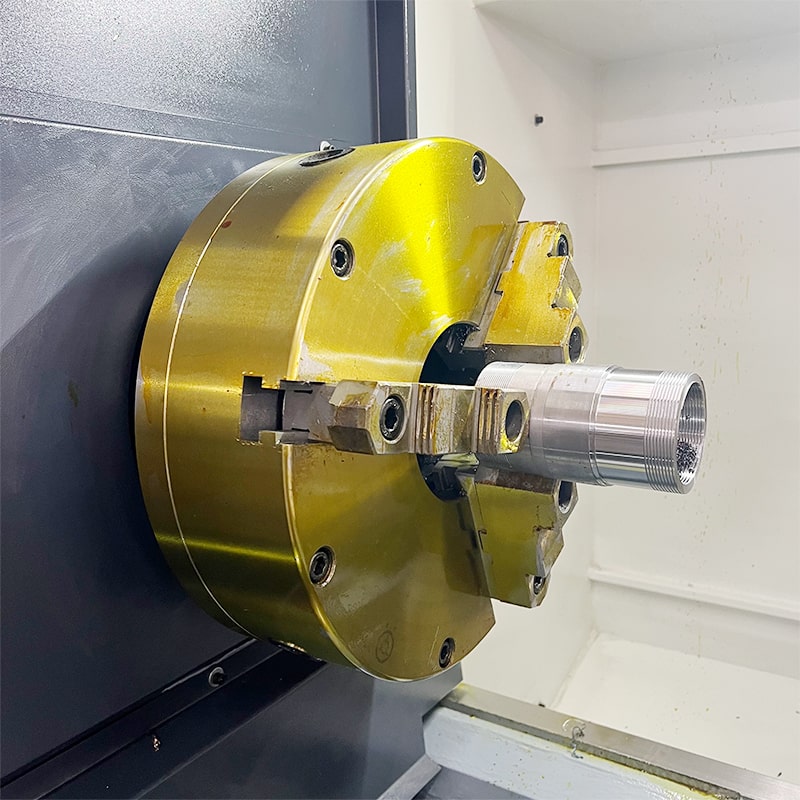

With a maximum machining diameter of 800 mm and a maximum machining length of 1500 mm, this model fully meets the demands of industries such as machinery manufacturing, energy, petroleum, mining, shipbuilding, and defense for large component processing. It is capable of efficiently performing operations such as external and internal turning, taper turning, grooving, drilling, and threading.

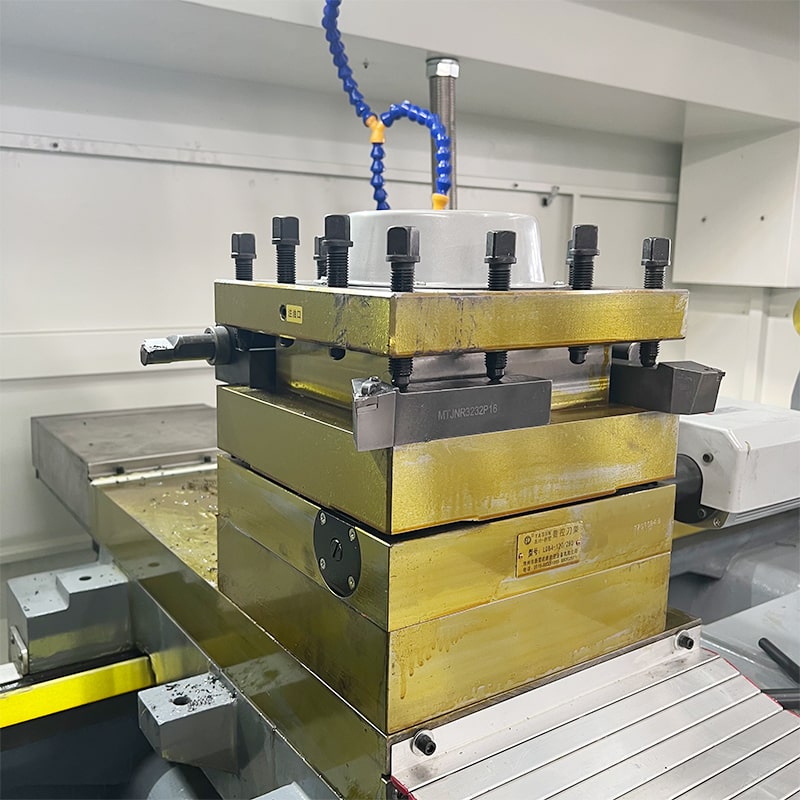

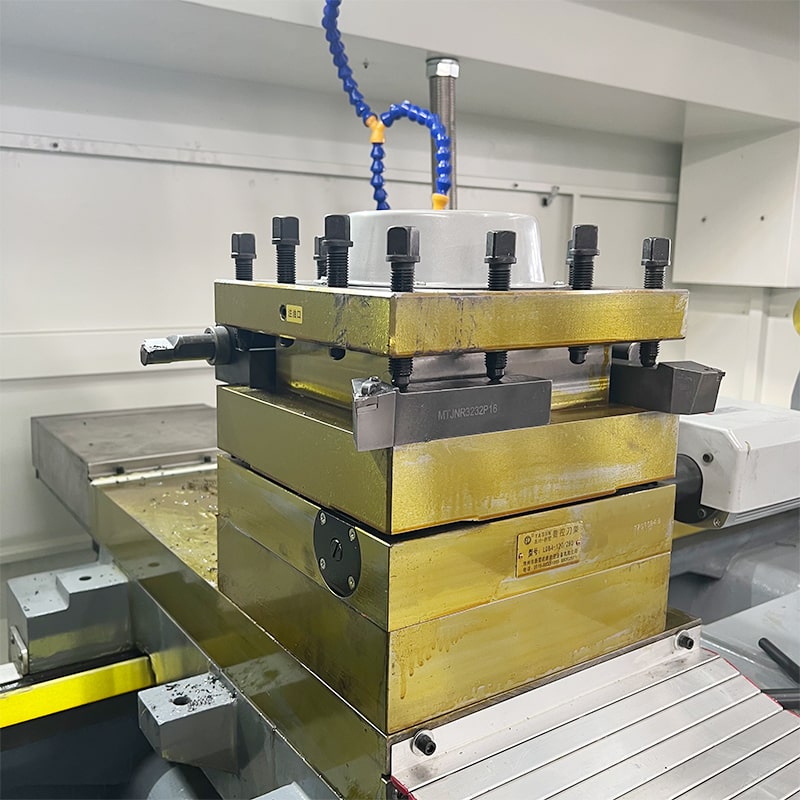

In terms of configuration, the CK6180×1500 is equipped with high-precision ball screws and linear guideways, combined with stable servo drives and an advanced CNC control system, ensuring machining accuracy and repeatability. The spindle system is dynamically balanced and provides high torque output, enabling smooth transitions between heavy cutting and high-speed cutting. The user-friendly interface simplifies program editing and operation, reducing operator workload.

Opcional

Knife tower : 4 ,6,8stations

Turntable : manual Turntable ,hydraulic Turntable

CNC system: GSK, KND, FANUC, Siemens, etc.

CK6180×1500 CNC Lathe – Advantages and Features

Main Features

Large-Diameter and Long-Length Machining Capacity

Maximum machining diameter up to 800 mm, maximum machining length 1500 mm, meeting the requirements for heavy-duty and oversized parts.

Suitable for efficient machining of shafts, disks, large sleeves, and other long or bulky components.

High-Rigidity Bed Structure

The bed is made of an integral casting, stress-relieved to eliminate internal stress and ensure long-term stability without deformation.

Wide, wear-resistant guideways guarantee stability and service life even under heavy cutting conditions.

High-Precision Transmission System

Equipped with high-precision ball screws and linear guideways, offering high transmission efficiency and low friction.

Excellent positioning and repeatability accuracy ensure precise dimensions of machined parts.

Powerful Spindle System

The spindle is supported by high-precision bearings and provides high torque output.

Capable of both low-speed heavy cutting and high-speed finishing to meet diverse machining requirements.

Advanced CNC Control System

Compatible with mainstream CNC systems such as FANUC, Siemens, or domestic brands like GSK.

Flexible program editing, user-friendly operation interface, and support for multiple automatic machining cycles.

Efficient Chip Removal and Cooling

Equipped with a strong cooling system to ensure stable cutting and extend tool life.

Automatic chip removal reduces downtime and improves overall productivity.

User-Friendly Design

Control panel layout is ergonomic, interface is clear and intuitive, reducing operator workload.

Easy maintenance and servicing, minimizing machine downtime.

Key Advantages

Wide Machining Range – capable of handling large-diameter, long-length, and multiple types of parts.

Stable and Reliable – robust structure and high-quality components ensure long-term stable operation.

High Precision – ball screws, guideways, and servo systems guarantee machining accuracy.

High Productivity – suitable for both batch production and flexible single-piece processing.

Labor-Saving – high automation reduces manual intervention and operator intensity.

Wide Applications – widely used in machinery manufacturing, energy equipment, petrochemical, mining, shipbuilding, defense, and metallurgy industries.

The CK6180×1500 CNC Lathe combines large-scale machining capacity, high rigidity, precision, and efficiency. It is the ideal choice for processing oversized components, helping enterprises enhance production capacity, reduce manufacturing costs, and strengthen competitiveness.

| Project | Content | Unit | ALCK6180*1500 |

| Processing range | Maximum turning diameter of bed | mm | Φ800 |

| Maximum turning diameter on skateboard | Φ440 | ||

| Maximum processing length | mm | 1500 | |

| Maximum machining diameter | mm | Φ800 | |

| Maximum bar diameter | mm | Φ440 | |

| Spindle | Chuck | 400 three claws/630 four claws | |

| Spindle head form | A211 | ||

|

Spindle hole diameter

|

mm | Φ105 | |

| Feed | X/Z axis travel | mm | 420/1500 |

| X/Z axis screw diameter × pitch | mm | φ3208/φ5010 | |

| X/Z fast moving speed | m/min | 4/6 | |

| Tool holder | Tool holder form | Electric vertical | |

| Number of stations | 4 | ||

| Motor | Spindle motor power | Kw | 11 |

| Spindle motor torque | NM | 48 | |

| Other | Machine weight | kg | 4500 |

| Machine size: length×width×height | mm | 3990/1900/2000 |

CK6150×1500 CNC Lathe — Industry Applications

Mechanical Manufacturing Industry

The CK6150×1500 is widely used in the production of general mechanical parts such as shafts, bushings, screws, nuts, and couplings. Its stable cutting performance ensures machining accuracy and consistency, meeting the needs of both small-batch and large-scale production.

Automotive Industry

The lathe is suitable for machining critical components such as transmission shafts, wheel hubs, brake drums, and engine housings. These parts require high concentricity and surface finish, and the machine provides efficient processing solutions for automotive parts production.

Mold Industry

The CK6150×1500 can be used to process mold bases, inserts, and cavity components. Its high rigidity and precision allow for precise turning of molds, ensuring part accuracy and extending the service life of the molds.

Energy Industry

In the energy sector, the lathe is used for the machining of wind power shafts, turbine components, and large bearings. The large machining length (1500 mm) allows it to handle long-shaft parts, meeting the high-strength and high-stability demands of the energy industry.

Aerospace Industry

The aerospace sector requires high precision and reliability. The CK6150×1500 is used to process turbine shafts, landing gear parts, and various structural components. The machine’s high precision ensures safe and stable operation of aircraft.

Shipbuilding Industry

This lathe is widely applied in the machining of propeller shafts, bearings, and other marine components. Its strong adaptability makes it suitable for large and long parts processing, fully meeting the requirements of shipbuilding.

Hardware and Tool Manufacturing

The CK6150×1500 is also suitable for processing hardware accessories and tool parts such as wrench handles, pipe fittings, and threaded parts. With efficient cutting and stable performance, it improves product consistency and production efficiency.

CK6150 CNC Lathe – FAQ

What is the main application of CK6150?

The CK6150 CNC lathe is mainly used for machining shafts, discs, sleeves, and other complex surfaces. It can perform turning, facing, threading, and various operations, suitable for both batch and single-piece production.

What is the maximum swing over bed?

The maximum swing over bed is typically 500–630 mm, depending on the manufacturer’s configuration.

What is the machining length?

The standard machining length is 1500 mm, suitable for processing long shaft parts.

What is the spindle bore diameter?

The spindle bore diameter is usually 82 mm, allowing clamping of larger bars and tubes.

What type of tool post does it use?

It is equipped with a 4-station electric tool post as standard, with optional 6 or 8 stations available for different machining needs.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More