CK6150 CNC Lathe – High-Precision Cutting, a Stable and Reliable Machining Tool

Brand - ALLES CNC

Model - ALCK6150*1000

Dimensions - 3030×1600×2050mm

Price - $9999(Standard Edition)/$13500(Pro Edition)

Availability - 400 pieces of inventory available for sale every month

Certification - Meeting CE Standards in Terms of Quality & Safety

Payment Method - T/T/ Credit Cards

One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

VIDEO CONTACT US

VIDEO CONTACT US

Product Description

CK6150×1000 CNC Lathe Machine Introduction

The CK6150×1000 CNC lathe is a high-performance medium-to-large turning machine, designed to meet the demands of precision machining for a wide range of metal components. It offers a maximum swing over bed of Φ500 mm and a maximum machining length of 1000 mm, making it ideal for medium and large workpieces. The machine is built with a high-rigidity one-piece cast bed, ensuring long-term stability and reliability.

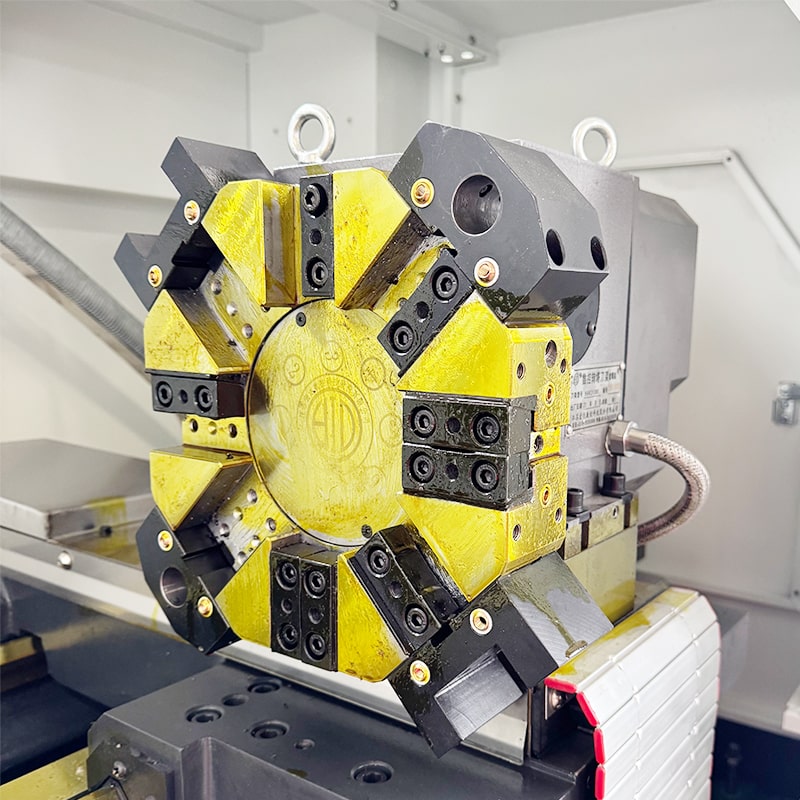

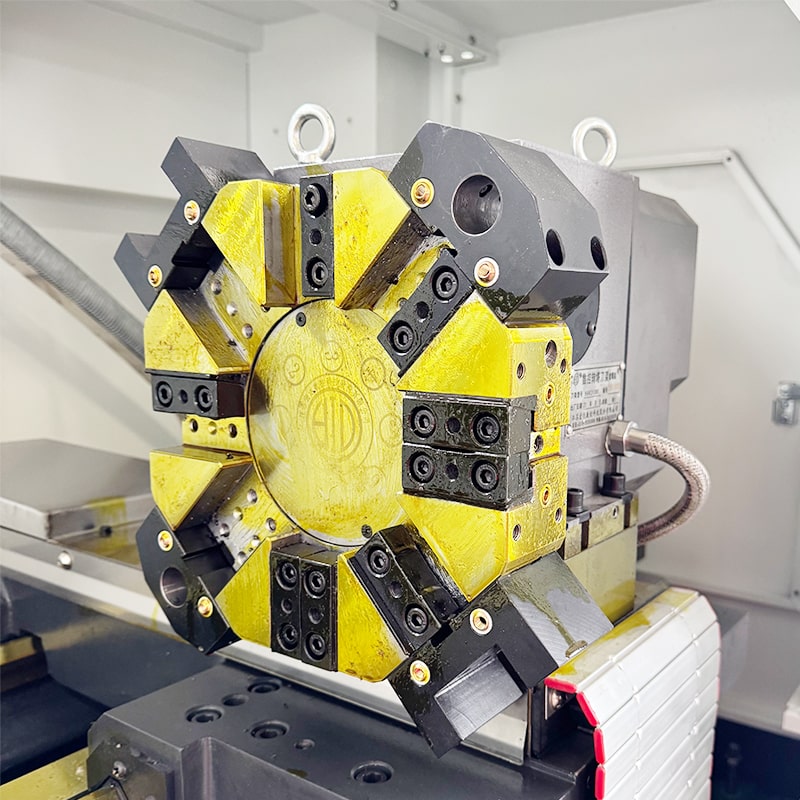

Equipped with a spindle bore of Φ82 mm and a speed range of 60–2000 rpm, it provides strong cutting power and flexibility for various materials. The X/Z axes feature a minimum increment of 0.001 mm, while the tool post repeat positioning accuracy reaches ≤0.004 mm, guaranteeing consistent machining accuracy. With a 4-station electric tool post and 25×25 mm tool holders, it supports multi-process continuous machining, significantly improving efficiency.

The overall machine dimensions are 3030×1600×2050 mm, with a weight of approximately 2500 kg. Suitable for both single-piece and small-batch customized production, as well as mass production, the CK6150×1000 is widely used in machinery manufacturing, automotive, mold making, aerospace, and energy equipment industries. With its excellent cutting capability, stability, and versatility, it is the ideal choice for enhancing productivity and machining quality.

Opcional

1.Knife tower - 4 ,6,8stations

2.Turntable - manual Turntable ,hydraulic Turntable

3.CNC system - GSK, KND, FANUC, Siemens, etc.

Advantages and Features of the CK6150×1000 CNC Lathe

Key Advantages

High Precision Machining

Equipped with an advanced CNC system and a rigid bed design to ensure dimensional accuracy and excellent surface finish.

Large Machining Capacity

Stable and Reliable

One-piece cast bed with strong rigidity, resistant to deformation, suitable for long-term continuous operation.

Easy Operation

User-friendly CNC interface, simple programming, and support for multiple machining processes.

High Production Efficiency

Optimized cutting parameters for batch production, significantly improving efficiency and reducing costs.

Wide Applications

Suitable for machinery manufacturing, automotive, aerospace, mold making, energy, and heavy industry.

Main Features:

Model - CK6150×1000

Rigidity - One-piece bed design with high-strength guideways ensures long-term stable performance

Cutting Performance - Equipped with a high-power spindle motor, capable of machining steel, alloys, and other tough materials

CNC System - Optional systems such as GSK, FANUC, or Siemens for flexible operation

Tool Configuration - Four-position electric tool post, supporting multi-process continuous machining and improving efficiency

Versatility - Suitable for both single-piece and small-batch customized production, as well as mass production

| Item | Unit | ALCK6150*1000 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1000 |

| X/Z axis maximum stroke | mm | 300/1000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Spindle speed limit | rpm | 150-2000/60-1600 |

| Main motor power (frequency conversion) | kW | 7.5 |

| Frequency converter | kW | 7.5 |

| X/Z axis | N.m | 5/7.5 |

| X/Z axis rapid traverse speed | m/min | 6/8 |

| Tool holder type | 4-station tool holder (Wen chang) | |

| Tool bar size | mm | 25*25 |

| Diameter of tailstock sleeve | mm | Φ65 |

| Weight | Kg | 2500 |

| Machine size | mm | 3030*1600*2050 |

Main Application Industries

Machinery Manufacturing

Suitable for machining various shafts, sleeves, and disc-type components.

Widely used in the production of machine tool parts, bearings, and transmission components.

Ensures higher assembly accuracy and longer service life of parts through precision cutting.

Automotive Industry

Extensively applied in the machining of engine components, drive shafts, brake drums, and gears.

Supports mass production, ensuring consistency and reliability of parts.

Helps automotive manufacturers improve productivity and reduce production costs.

Aerospace Industry

Capable of meeting the high-precision and high-strength requirements of aerospace components.

Suitable for machining complex contour shafts and high-strength alloy parts.

Guarantees product consistency and reliability, meeting strict safety standards.

Mold Manufacturing

Ideal for machining high-precision mold components such as inserts and cavity parts.

Produces excellent surface finishes, reducing the need for post-processing like polishing.

Shortens mold development cycles and enhances overall production efficiency.

Energy and Heavy Industry

Applicable for machining large components used in power equipment, petroleum machinery, and construction machinery.

Delivers strong cutting power, capable of handling high-strength materials.

Meets both precision and stability requirements for heavy-duty equipment components.

CK6150 CNC Lathe Customer Notice

Dear Customer,

Thank you for choosing the CK6150 CNC Lathe manufactured by our company. To ensure safe and efficient operation of this equipment, please carefully read the following instructions:

1. Installation and Environmental Requirements

The machine should be installed on a solid and level foundation to prevent uneven flooring from affecting machining accuracy.

The operating environment should be clean and dry, avoiding excessive moisture, dust, or strong vibrations.

Recommended ambient temperature: 10℃–40℃, avoiding prolonged exposure to high or low temperatures.

Allow sufficient space around the machine for operation, maintenance, and heat dissipation.

2. Electrical and Operational Safety

The machine must be connected to a proper three-phase power supply (380V/50Hz or customer-specified voltage) with reliable grounding.

Operators must be professionally trained and familiar with CNC system operations and safety regulations.

Before starting the machine, check that the emergency stop switch is functioning properly and that all safety devices are in place.

Never reach into the working area or touch rotating parts while the machine is in operation.

3. Usage and Maintenance

Ensure that the workpiece is securely clamped, the correct tools are selected, and the program is properly set before machining.

Avoid overload cutting during operation to prevent damage to the spindle or tools.

Check the lubrication system daily, and keep guideways and lead screws adequately lubricated.

Regularly clean chips and coolant to maintain machine cleanliness and prevent blockages or corrosion.

Inspect electrical, hydraulic, and transmission components according to the maintenance schedule, and replace wear parts in a timely manner.

4. Warranty and Service

The machine has a 12-month warranty (starting from the date of arrival at the customer’s site).

During the warranty period, we provide free repair or replacement for parts damaged due to product quality issues.

Damage caused by non-quality issues (such as misuse, improper operation, or power abnormalities) will incur service charges as appropriate.

Our company provides long-term technical support and spare parts supply to ensure smooth operation of your equipment.

5. Special Notes

Before use, please carefully read the Operation Manual and strictly follow all operating procedures.

It is recommended that customers maintain a machine record to track operation status and maintenance history.

In case of a fault, immediately stop the machine and contact after-sales service personnel. Do not attempt to disassemble or repair the machine yourself.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More