Slant Bed CNC Lathe For Parts

Higher accuracy Taiwan linear guideways Higher speed spindle unit, Optional home.

slant bed lathe is suitable for precise and efficient machining of shaft and disc parts

slant bed lathe It is widely used in the processing of shaft parts and disc parts.

Precision machining of complex shaped parts on slant bed lathe.

The advantages of the inclined bed turning-milling compound machine are to reduce.

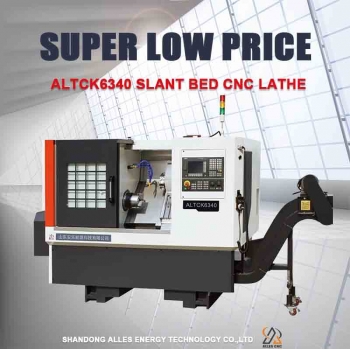

ALTCK6340 Horizontal Slant Bed CNC Lathe for Metal

Flat bed/45 degrees slant bed CNC lathe machine,High-precision Taiwan guide rail,.

TCK6340 Slant Bed Turning Center Linear Guideway Cnc Automatic Lathe

CNC lathe manufacturers manufacture CNC inclined cars, TCK6340 CNC lathe with in.

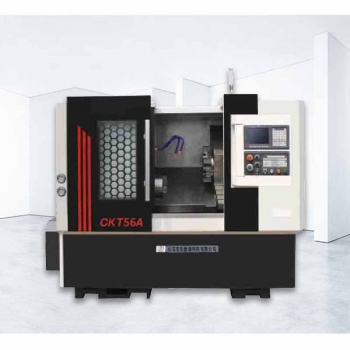

Slant Bed CNC Lathe CNC Turning Center TCK50Ax500

Full-automatic slant bed gang type cnc lathe TCK50A 5 axis mini slant bed cnc lat.

slant bed cnc lathe machining workpiece

ALLES CNC metal lathe can be widely used in automotive/truck, aerospace, medical .

Slant Bed CNC Lathe And Milling for Metal

Model: ALTCK46A Brand: ALLES CNC Specifications Unit ALTCK46A Max. swing over bed.

What is a CNC Slant Bed Lathe?

A CNC Slant Bed Lathe is a high-precision and high-efficiency CNC turning machine.

It adopts an integrated 30° or 45° slant bed structure, combined with a high-rigidity spindle and high-precision linear guideways, ensuring excellent chip removal, cutting rigidity, and positioning accuracy.

Compared with traditional flat-bed lathes, the slant-bed design offers significant advantages in rigidity, precision retention, operator ergonomics, and automation compatibility.

Main Application Industries

1. Automotive Parts Manufacturing

Used for precision turning of engine shafts, hubs, transmission shafts, and piston rods. Offers high machining accuracy and fast production cycles.

2. Hardware and Mechanical Components

Widely used for flanges, couplings, threaded parts, and shaft components in small to medium batch automated production.

3. Hydraulic and Pneumatic Industry

Efficiently machines hydraulic cylinders, piston rods, valve cores, and valve bodies, ensuring excellent surface finish and sealing precision.

4. Electronics and Instrumentation

Suitable for high-precision machining of small shafts, connectors, and electronic housings.

5. Mold and Tooling Manufacturing

Used for mold locating pins, guide posts, and fixture parts, requiring high dimensional accuracy.

6. Energy and Equipment Manufacturing

Widely applied in motor shafts, pump shafts, and wind turbine components, providing stable performance for heavy-duty and high-precision machining.

Frequently Asked Questions (FAQ)

1. What is a slant bed CNC lathe?

A slant bed CNC lathe has its saddle set at an angle (usually 45°) to the bed.

Compared with a flat-bed lathe, it offers better chip removal, higher rigidity, and improved operator visibility.

2. What is the difference between linear guideways and box (hard) ways?

Linear guideways: Low friction, smooth movement, high positioning accuracy — ideal for high-speed precision machining.

Box ways: Strong rigidity and vibration resistance — suitable for heavy cutting.

Machines with linear guides are preferred for users focusing on speed and precision.

3. What materials can be machined?

Suitable for carbon steel, stainless steel, cast iron, copper, aluminum alloy, and titanium alloy, covering a wide range of light and heavy cutting tasks.

4. How to choose the right model?

Consider the following:

Workpiece size (maximum turning diameter and length)

Type of parts (shaft, disc, or threaded)

Production volume (single piece, small batch, or mass production)

Automation requirements (bar feeder or robotic arm integration)

5. What are the daily maintenance tips?

Clean chips and keep the guideways clean daily.

Check spindle lubrication and cooling systems regularly.

Verify turret indexing accuracy.

Inspect ball screw clearance and servo condition periodically.

Apply anti-rust and anti-moisture treatment during long shutdowns.

6. What are the advantages of a Slant Bed and Linear Guide Way CNC Lathe?

High machining accuracy and efficiency

Smooth chip removal for long-time operation

Excellent stability and operator comfort

Supports automation and robotic integration

Easy maintenance and long-term precision retention