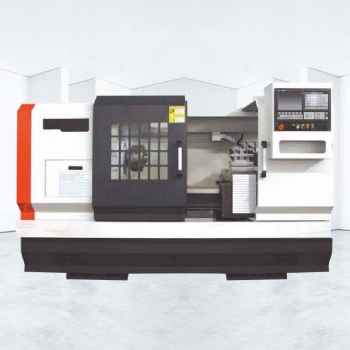

CK61125E heavy duty cnc automatic flat bed cnc turning lathe machine

CK61125E horizontal cnc lathe machines are heavy-duty CNC machine tools, which ar.

CK6185E automatic cnc lathe machine

CK6185E is a fully automatic lathe with high precision and high efficiency. The l.

CK6130 horizontal cnc lathe machine for instrumentation industry

CK6130 cnc turning lathe adopts mechatronics design, beautiful appearance, reason.

CNC Turning Milling Machine for machining metals

ALCK6180X1500 ALLES CNC lathe Maximum machining workpiece length:1500mm Rail wid.

CNC lathe machining parts

automatic cnc lathe compact overall layout and small footprint Independent spindl.

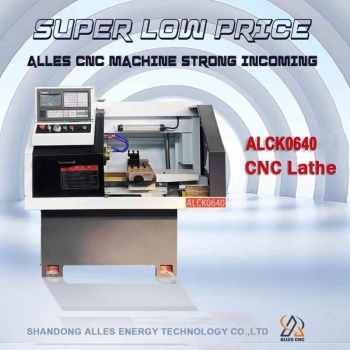

Horizontal Metal Cutting Lathe Pneumatic Chuck

CK0640 Horizontal Metal Cutting Lathe Pneumatic Chuck CK0640 horizontal metal cut.

Flat Bed CNC Lathe Part Machining

The optimized design of automatic cnc lathe headstock is suitable for turning of .

CNC Lathe Machining Metal

Equipment Configuration And Parameters Name Project ALH32i The main parameters Ma.

CNC Horizontal Lathe Machine for Parts Manufacturing

cnc lathe processing is mainly used to process various shaft and disc parts. It c.

CNC Lathe Machining Of Auto Parts

Flatbed CNC lathe has the following characteristics: High machining precision and.

CNC Lathe Machining Metal Parts

Horizontal CNC Lathe is suitable for large, medium and small batches, multi-varie.

CNC turning machining of auto parts

Automatic cnc lathe better solves the problem of complex, precise, small batch an.

Horizontal Mini Cnc Lathe Machine

CNC machine tools better solve the problem of complex, precise, small batch, and .

CNC lathe used in construction machinery

flat bed CNC lathe Processing of small plate parts, disc parts, and shell parts i.

CNC Lathe Machining Metal

CNC lathe is an automatic cnc lathe with high precision and high efficiency. Equi.

CNC Lathe Machining Metal

CNC lathe is an automatic cnc lathe with high precision and high efficiency. Equi.

CNC Lathes Metal Industrial Machinery

Automatic CNC lathe is a high-precision and high-efficiency automatic machine too.

CNC lathes Are Used In The Machinery Industry

Automatic cnc lathe CNC lathe is a high-precision and high-efficiency automatic m.

What is a Flat Bed CNC Lathe?

A Flat Bed CNC Lathe is a CNC turning machine that combines high precision, high efficiency, and cost-effectiveness.

It adopts a flat bed structure equipped with high-precision linear guideways and a servo drive system, ensuring smooth feed motion and excellent repeat positioning accuracy.

The machine features a simple and compact design, reasonable layout, easy maintenance, and strong operability.

Compared with traditional box-way lathes, linear guideways offer lower friction and smoother movement, making this model especially suitable for high-speed precision machining and batch production of small and medium-sized components.

Main Application Industries

1. Automotive Parts Manufacturing

Used for machining small shafts, hubs, flanges, nuts, and connectors, ensuring dimensional consistency and high surface quality.

2. Machinery and Hardware Components

Widely used for batch processing of shafts, discs, threaded parts, and coupling sleeves, ideal for small and medium-sized enterprises.

3. Hydraulic and Pneumatic Components

Suitable for machining valve bodies, valve cores, piston rods, and fittings with high sealing and surface finish requirements.

4. Electronics and Instrumentation

Used for precision turning of small shafts, connector housings, and fittings, meeting high-speed and high-precision machining demands.

5. Mold and Tooling Industry

Used for producing mold accessories, guide pillars, locating pins, and fixture parts that require high assembly accuracy.

6. Energy Equipment Manufacturing

Applied to precision machining of motor shafts, pump shafts, and small wind power components, ensuring rigidity and stability.

Frequently Asked Questions (FAQ)

1. What is the difference between linear guideways and box (hard) ways?

Linear guideways: Low friction, fast movement, high positioning accuracy — ideal for high-precision and light cutting.

Box ways: Strong rigidity and vibration resistance — suitable for heavy cutting and large workpieces.

Linear guideways are better suited for high-speed and automated turning.

2. What materials can be machined?

Suitable for a wide range of metals:

Carbon steel, stainless steel, cast iron, copper, aluminum, alloy steel, and titanium alloy.

Supports both light and moderate cutting operations.

3. How to choose the right flat bed CNC lathe model?

Consider the following factors:

Workpiece size (maximum swing diameter and machining length)

Type of parts (shaft, disc, or threaded components)

Production volume (single-piece, small batch, or continuous production)

Precision and surface finish requirements

Automation level (bar feeder or robotic arm integration)

4. What are the daily maintenance points?

Clean chips daily and keep guideways clean and lubricated.

Regularly check spindle bearing temperature and noise.

Ensure turret indexing is accurate and smooth.

Periodically inspect servo motor backlash and ball screw clearance.

Apply rust and moisture protection during long-term shutdowns.

5. What are the advantages of a flat bed linear guide CNC lathe?

Compact structure and easy operation.

High machining precision and fast processing speed.

Low maintenance cost and excellent cost-performance ratio.

Suitable for automation and batch production.

Capable of handling both light and moderate cutting tasks efficiently.